A question we hear at The CECON Group is “Why are pharmaceutical companies increasingly seeing the need to hire outside consultants?”

We approached Dr. Barry Bowen, CECON Vice President and Program Manager, a consultant with more than 35 years of experience in business leadership, human resources, and technical project management. He offered his observations regarding the areas where companies are using outside consultants in the pharmaceutical industry.

Dr. Bowen has noticed the following trend in client needs:

- Temporary quality control management;

- Audit and reporting expertise;

- CRO/CMO selection and compliance/audit functions;

- New molecule research, including literature and lab work;

- Assistance with strategy for new molecule clinical studies for future FDA acceptance;

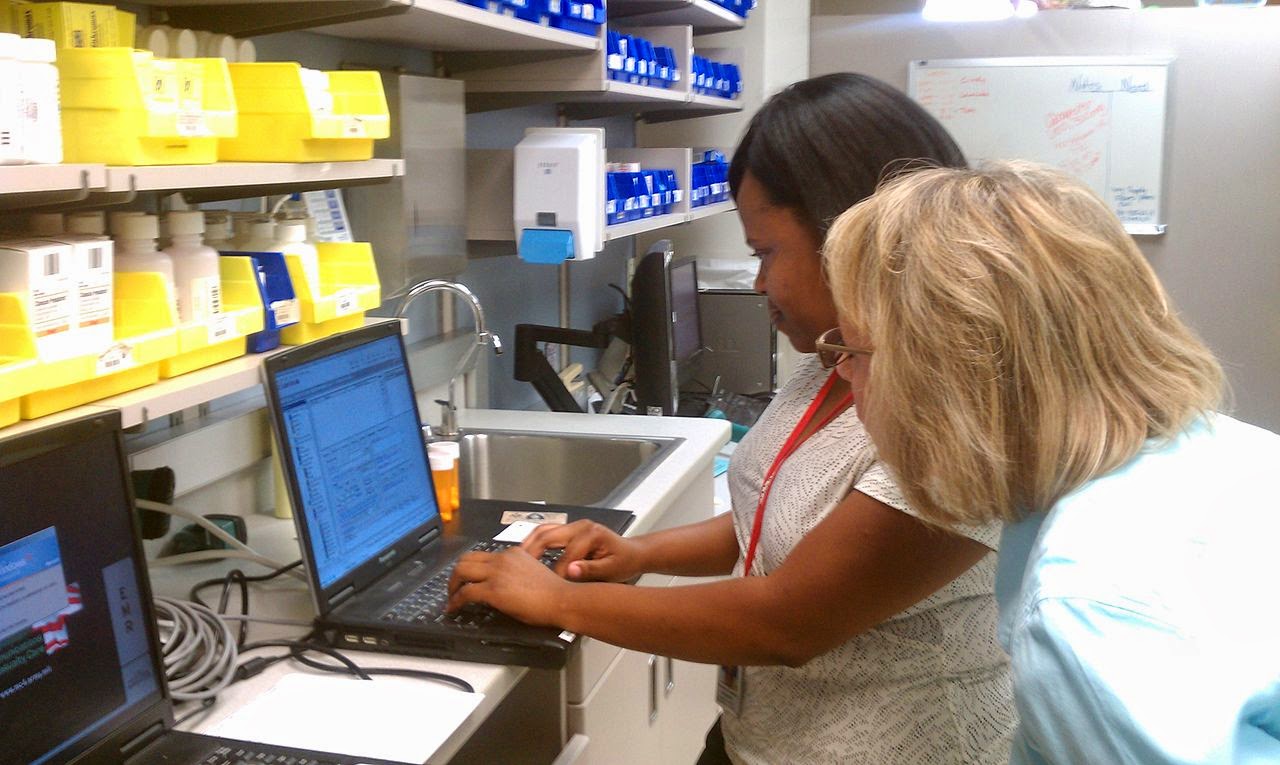

- FDA compliance of internal software and computer systems.

We asked Dr. Bowen what was driving these trends.

“These trends are partly due to pharma’s evolving business strategy to gain more growth and more profit from existing product portfolios, rather than high emphasis on filling the pipeline with potential winners. This business model may mean purchasing more research, ingredients or products, all of which must be vetted and tracked for quality and compliance. It may mean protecting intellectual property more vigorously or simply paying more attention to efficiencies of established internal systems. Engaging career pharma specialists, consultants, and expert witnesses for relatively short periods of time, can often be faster and better investments than waiting for new employees to mature.”

A long-time CECON pharmaceutical consultant and former FDA Science Branch Director has noticed another trend: Outsourcing of production of pharmaceuticals themselves. He has observed:

“Pharma production outsourcing occurs because it is cheaper than making it in-house. Labor rates are lower and companies avoid capital expenditures on new (brand new or replacement) equipment. However, firms are starting to see that they have a false economy. There are many cases of API (active pharmaceutical ingredient) contamination, and out-of-specification final products occurring. This is because "you get what you pay for." Buy cheap and get cheap. Pharma executives are beginning to realize this.

Firms are finding out that foreign made products can be problematic. FDA directed company recalls of finished products are occurring. FDA 483s and Warning Letters are being issued. The challenge is to select a quality company when outsourcing, which can cost more and take more time.

My recommendation is that if you contract out, do it in the United States. It will cost more, but you can visit facilities and inspect them readily yourself, thereby avoiding problems. I see that happening now, yet slowly; outsourcing continues, but it will be with domestic firms.”

In the March 3, 2014 issue of Chemical and Engineering News, a series of case studies is detailed in the article “From the Lab to the Production Plant.” The article’s author, Michael McCoy, notes that “Often innovation occurs at small entrepreneurial firms. Typically started by visionary men and women, these companies have great ideas and skilled scientists, but they rarely have the resources to make their molecules at large enough scale or with consistent enough manufacturing processes for use in clinical trials.” Production is then outsourced to contract manufacturers.

Have you noticed any additional trends in outsourcing?

Founded in 1985, CECON specializes in providing science and engineering consultants and expert witnesses. Consultants in their global network typically have more than 25 years of experience; CECON offers consultants in more than 200 disciplines, including pharmaceutical development and regulatory compliance, chemical processing and safety, biotechnology, medical devices,nanotechnology, and polymers and coatings.